The Internet of Things (IoT) revolutionizes predictive electrical maintenance by using smart sensors, connected meters, and real-time data analysis to monitor systems and detect issues early. Key benefits include reduced downtime, lower maintenance costs, and enhanced safety through proactive alerts. Challenges like data security and initial setup costs can be managed with secure devices and strategic planning. Implementing IoT transforms traditional maintenance into a smarter, safer, and more efficient process, making it ideal for both homeowners and businesses.

Do your lights flicker out of nowhere or your power goes down when you least expect it? It’s frustrating, right? Electrical maintenance is usually something we only think about when something goes wrong, but what if you could stop those problems before they even start?

That’s where predictive maintenance and the Internet of Things (IoT) come in. These smart technologies can predict and prevent electrical issues, saving you time, money, and a whole lot of headaches. Let’s dive in and see how it all works!

Understanding Predictive Maintenance

Predictive maintenance is a proactive approach to electrical maintenance that prevents problems before they occur.

Instead of waiting for something to break, this method uses technology to monitor equipment and fix issues before they cause trouble. It’s a smarter, more efficient way to keep everything running smoothly.

What is Electrical Maintenance?

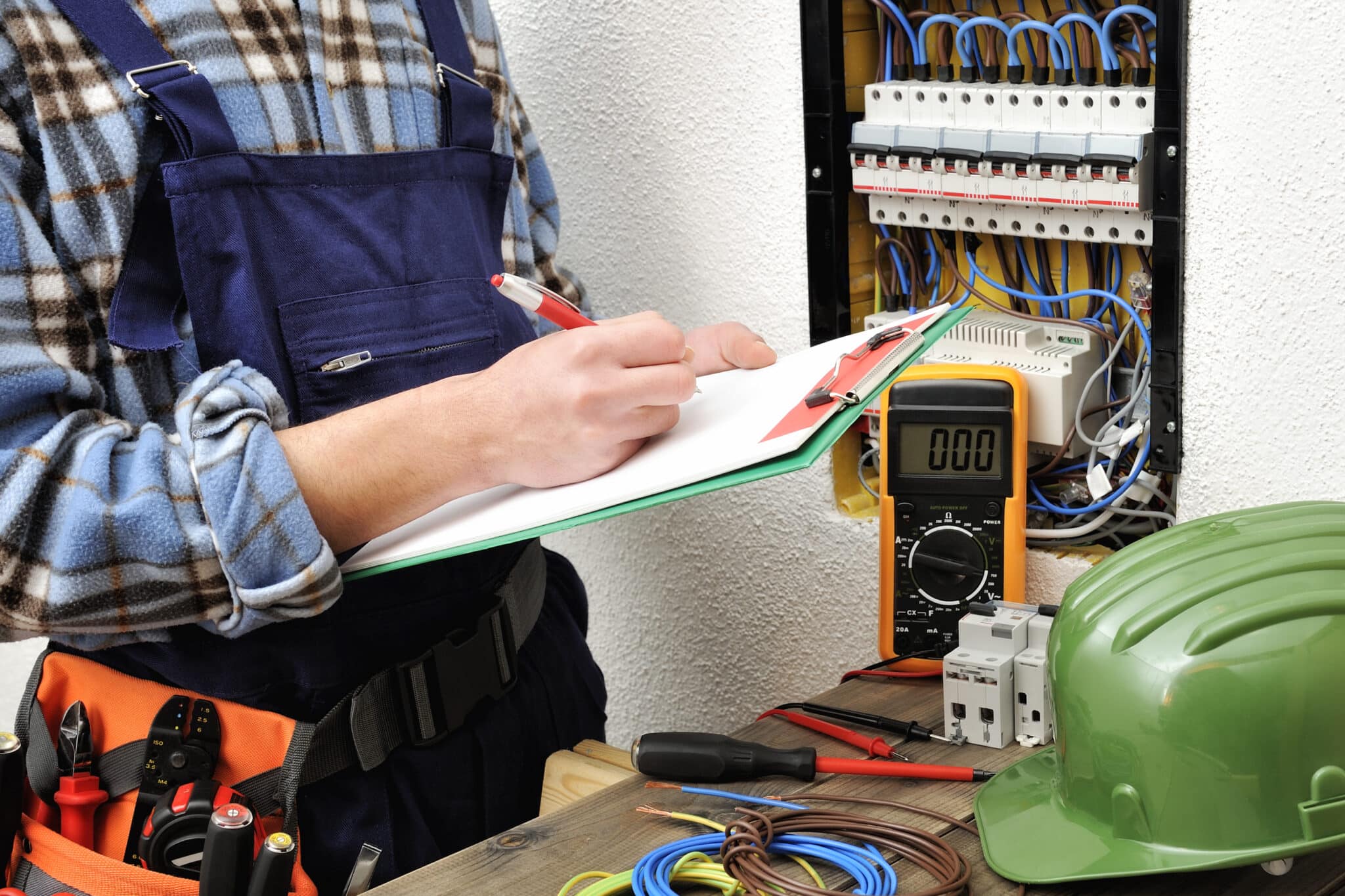

Electrical maintenance involves checking, testing, and repairing electrical systems to ensure they are safe and functioning correctly. This can include anything from replacing a faulty switch to inspecting complex electrical setups in homes or businesses.

Regular maintenance helps prevent risks like electrical fires or unexpected power outages, keeping everything working as it should.

The Traditional Way vs. Predictive Maintenance

The traditional approach to electrical maintenance has always been reactive. You notice a problem, like a blown fuse or a flickering light, and then you fix it. While this method works, it often leads to unexpected breakdowns and can be inconvenient.

Predictive maintenance changes the game by using advanced tools and data to predict when a problem is likely to happen. This way, you can address issues early, saving time, money, and stress.

Understanding IoT (Internet of Things)

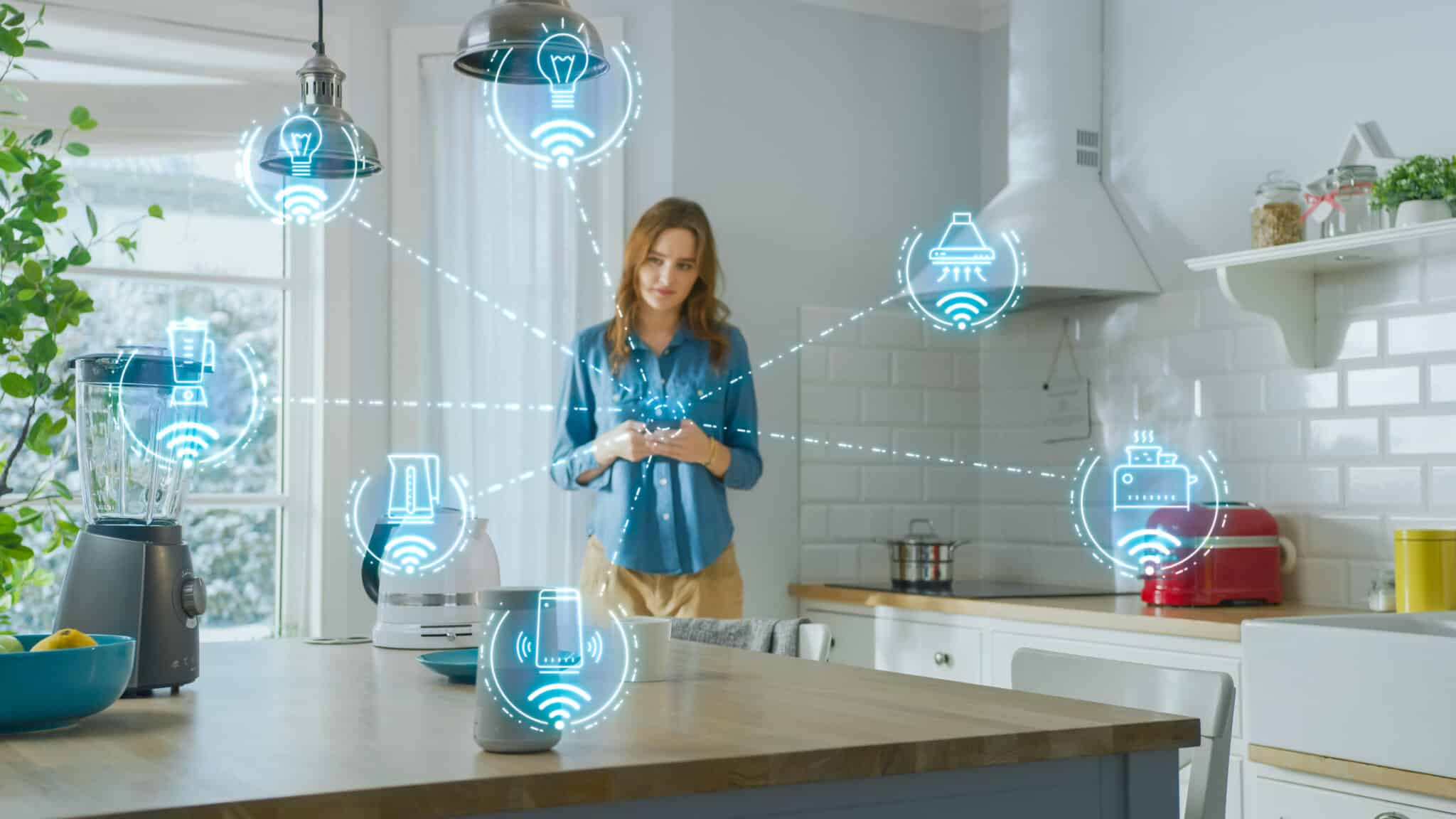

The Internet of Things, or IoT, is all about connecting everyday devices to the Internet, allowing them to send and receive data. From smart thermostats to fitness trackers, IoT devices are everywhere, making our lives easier and more connected.

But it’s not just about convenience—IoT plays a huge role in industries, especially when it comes to predictive electrical maintenance.

What is IoT?

IoT refers to a network of physical devices, like sensors, meters, and appliances, that communicate with each other through the internet. These devices collect and share data, which can then be used to monitor and control different systems.

For example, smart sensors in an electrical system can track energy usage or detect faults, providing valuable information that helps maintain and optimize equipment.

How IoT Connects Devices and Collects Data

IoT devices work by gathering data from their surroundings and transmitting it to a central system, where it can be analyzed. This connectivity allows for real-time monitoring and the automation of processes that would otherwise need manual checks.

In the context of electrical maintenance, IoT can connect various pieces of equipment, like circuit breakers and transformers, to create a network that constantly monitors their performance.

How IoT is Changing Electrical Maintenance

IoT is revolutionizing electrical maintenance by making it smarter and more efficient. Instead of waiting for something to go wrong, IoT allows real-time monitoring and predictive analysis, which means problems can be fixed before they even happen.

This shift from reactive to proactive maintenance helps keep systems running smoothly and reduces the risk of costly breakdowns.

Monitoring Equipment in Real-Time

One of the biggest advantages of IoT in electrical maintenance is real-time monitoring. With IoT devices like smart sensors and connected meters, you can keep a constant eye on the performance of your equipment.

These devices collect data on things like temperature, energy usage, and voltage levels, providing instant alerts if something seems off. This real-time insight allows for quick responses to potential issues, preventing minor problems from turning into major failures.

Predicting Problems Before They Happen

IoT doesn’t just monitor equipment—it also helps predict future problems. By analyzing data trends, IoT systems can identify signs of wear and tear or other issues that might lead to a breakdown.

For instance, if a sensor detects that a motor is running hotter than usual, it can alert you to check it out before it overheats and fails. This predictive capability means you can schedule maintenance at the most convenient times, avoiding unexpected downtime.

Reducing Downtime and Saving Costs

With IoT, downtime is reduced significantly because problems are caught early. This means fewer disruptions and more consistent performance, whether it’s in a home or a business setting.

Additionally, by addressing issues before they escalate, you can avoid costly repairs and extend the lifespan of your electrical equipment. Overall, IoT helps save both time and money while ensuring a safer and more reliable electrical system.

Key IoT Devices Used in Electrical Maintenance

IoT devices are the backbone of predictive electrical maintenance, offering tools that help monitor, analyze, and manage electrical systems more effectively.

These devices make it possible to detect problems early, optimize energy usage, and keep everything running smoothly. Let’s look at some key IoT devices commonly used in electrical maintenance.

Smart Sensors: Detecting Issues Early

Smart sensors are tiny but powerful devices that keep a close watch on various aspects of electrical systems. They can monitor temperature, humidity, voltage, and even vibrations, collecting data that can indicate the health of equipment.

For example, if a sensor notices unusual heat in a circuit breaker, it can alert you to check it before it becomes a fire hazard. Smart sensors provide the real-time data needed to catch small issues before they turn into big problems.

Connected Meters: Tracking Energy Use

Connected meters, like smart energy meters, help track the amount of electricity being used in real time. These meters provide detailed insights into energy consumption patterns, which can help identify inefficiencies or areas where power usage spikes unexpectedly.

By keeping an eye on energy use, connected meters not only help in managing costs but also in spotting irregularities that might indicate a problem needing maintenance.

IoT Gateways: Linking Devices for Better Communication

IoT gateways are the devices that bring everything together. They act as the bridge between the sensors, meters, and the central system where all the data is analyzed.

Gateways ensure that all the IoT devices can communicate effectively, sending data back and forth seamlessly. This integration is crucial for a well-functioning predictive maintenance system, as it allows for the smooth flow of information and quick response times.

Benefits of Using IoT in Predictive Electrical Maintenance

Incorporating IoT into predictive electrical maintenance brings a host of benefits that go beyond just fixing things before they break. IoT makes maintenance smarter, safer, and more efficient, helping both homeowners and businesses keep their electrical systems in top shape.

Detecting Problems Before They Happen

One of the biggest advantages of IoT is its ability to detect problems before they actually occur. By continuously monitoring equipment through smart sensors and connected devices, IoT systems can identify unusual patterns or signs of wear and tear.

This early detection means that maintenance can be planned and carried out at convenient times, avoiding unexpected breakdowns and costly emergency repairs.

Reducing Downtime and Saving Money

Downtime can be a major hassle, especially in business environments where every minute counts. IoT helps reduce downtime by keeping a constant check on the health of electrical systems and predicting potential failures.

By addressing issues early, IoT can prevent equipment from failing altogether, which not only keeps things running smoothly but also saves money on expensive repairs and lost productivity.

Making Maintenance Safer and More Efficient

Safety is always a top priority when it comes to electrical systems, and IoT plays a significant role in enhancing safety measures. With real-time monitoring, IoT devices can alert you to any hazardous conditions, like overheating or high voltage, allowing you to take action before any harm occurs.

Moreover, by automating routine checks and providing precise data, IoT makes maintenance tasks more efficient, reducing the need for manual inspections and minimizing human error.

How Predictive Maintenance Helps Homeowners and Businesses

Predictive maintenance, powered by IoT, isn’t just for big companies with complex systems—it’s beneficial for homeowners and small businesses too.

By adopting predictive maintenance, you can keep your electrical systems in good shape, avoid unexpected issues, and ensure everything runs smoothly.

Preventing Electrical Failures at Home

For homeowners, predictive maintenance means fewer surprises when it comes to electrical problems. Instead of dealing with sudden power outages, flickering lights, or tripped circuits, IoT devices can monitor your home’s electrical system continuously.

This constant monitoring helps catch potential issues early, allowing for quick fixes that prevent more significant problems down the line. It’s like having an extra layer of protection for your home’s electrical safety.

Keeping Businesses Running Smoothly

In a business setting, even a brief electrical failure can disrupt operations, leading to lost revenue and frustrated customers. Predictive maintenance helps businesses stay ahead of these disruptions by ensuring all electrical equipment is performing optimally.

From keeping lights on in retail stores to maintaining critical systems in offices, predictive maintenance minimizes downtime and keeps everything running like clockwork. Businesses can focus on what they do best, without the worry of unexpected electrical hiccups.

Simple Steps to Start Using IoT for Electrical Maintenance

Getting started with IoT for predictive electrical maintenance doesn’t have to be complicated. By following a few straightforward steps, you can set up a system that keeps your electrical equipment in check and prevents problems before they happen. Here’s how you can begin:

Choosing the Right IoT Devices

The first step is picking the right IoT devices for your needs. This could include smart sensors to monitor voltage and temperature, connected meters to track energy use, and IoT gateways to link everything together.

It’s important to choose devices that are compatible with each other and can seamlessly integrate into your existing electrical systems. Look for options that are easy to install and provide the data insights you need.

Setting Up a Basic IoT System

Once you’ve chosen your devices, setting up a basic IoT system involves connecting your sensors and meters to a central hub or gateway. This hub will collect data from all the connected devices and send it to a platform where you can view and analyze it.

Many IoT solutions come with user-friendly apps or dashboards that make it easy to monitor your system from anywhere, giving you peace of mind whether you’re at home or on the go.

Monitoring and Maintenance Tips

With your IoT system up and running, the key to effective predictive maintenance is regular monitoring. Here are some tips to keep your system in top shape:

- Regularly Check Sensor Data: Keep an eye on the data from your sensors, and look out for any alerts or unusual readings that may indicate potential problems.

- Schedule Periodic Checks: Set up regular checks of your IoT devices to ensure they are functioning correctly and efficiently.

- Respond to Alerts Quickly: Address any alerts as soon as they appear to prevent small issues from becoming major problems.

- Keep Software Updated: Regularly update the firmware and software of your IoT devices to maintain security and performance.

- Review and Adjust Settings: Periodically review the settings and thresholds of your sensors to ensure they are optimized for your specific needs.

Staying proactive with these monitoring and maintenance tips will help you catch potential issues early and keep your electrical systems running smoothly.

Common Challenges and Solutions

While IoT brings many benefits to predictive electrical maintenance, there are a few challenges to consider. Fortunately, with the right approach, these hurdles can be overcome, making your maintenance system more effective and reliable.

Data Security: Keeping Information Safe

One of the main concerns with IoT is data security. Since IoT devices collect and transmit data, it’s essential to ensure this information is protected from cyber threats. To keep your data safe, make sure to use devices from reputable manufacturers that offer strong security features.

Regularly update your devices’ firmware and use secure networks with strong passwords. Implementing these security measures will help safeguard your system against potential breaches.

Initial Setup Costs: Planning for Investment

Another challenge is the initial cost of setting up an IoT system for predictive maintenance. While the upfront investment might seem high, it’s important to consider the long-term savings from reduced downtime and fewer repairs.

To manage costs, start with a basic setup and gradually expand as needed. Prioritize critical areas that will benefit most from predictive maintenance and add more devices over time as your budget allows.

Technical Hurdles: Getting the Right Support

Implementing IoT technology can sometimes feel overwhelming, especially if you’re not tech-savvy. To overcome technical hurdles, consider seeking support from professionals who specialize in IoT installations.

Many companies offer services to help set up and maintain IoT systems, ensuring everything runs smoothly. Additionally, take advantage of online resources and tutorials that can guide you through the process and help you get comfortable with the technology.

Keep Your Electrical Systems Running Smoothly with IoT!

Ready to take control of your electrical maintenance and prevent unexpected issues? At Mister Sparky of Charleston, SC, we specialize in integrating IoT solutions that keep your home or business safe and efficient.

Serving Charleston, Mt. Pleasant, Summerville, and surrounding areas, our expert team is here to help you stay ahead of electrical problems. Contact us today to learn how we can make your maintenance smarter!

Electrical Maintenance FAQs

What is IoT?

IoT, or the Internet of Things, refers to a network of connected devices that communicate with each other over the Internet. These devices, like smart sensors and meters, collect and share data to monitor and control various systems, making everything from homes to businesses smarter and more efficient.

How Does IoT Help in Electrical Maintenance?

IoT helps in electrical maintenance by providing real-time monitoring and predictive analysis of electrical equipment. With IoT devices, potential problems can be detected early, allowing for proactive maintenance that prevents unexpected breakdowns and reduces downtime.

Is Predictive Electrical Maintenance Expensive to Implement?

While there are initial costs involved in setting up predictive maintenance systems, the investment often pays off in the long run through reduced repair costs, less downtime, and extended equipment life. Starting with a basic system and gradually expanding can help manage costs.

How Can IoT Improve Safety in Electrical Maintenance?

IoT improves safety by continuously monitoring electrical systems and alerting users to any dangerous conditions, such as overheating or abnormal voltage levels. This allows for timely interventions that can prevent accidents and ensure a safer environment.

What Are the Main Challenges of Using IoT in Electrical Maintenance?

The main challenges include ensuring data security, managing initial setup costs, and overcoming technical hurdles. These can be addressed by using secure devices, planning investments wisely, and seeking professional support for setup and maintenance.