Is your home equipped with aluminum wiring, and are you concerned about the potential safety hazards it might pose?

Many homeowners are unaware of the significant risks associated with this type of wiring. In this article, we’ll explore why this type of wiring is a serious concern and what you can do to ensure your home’s safety.

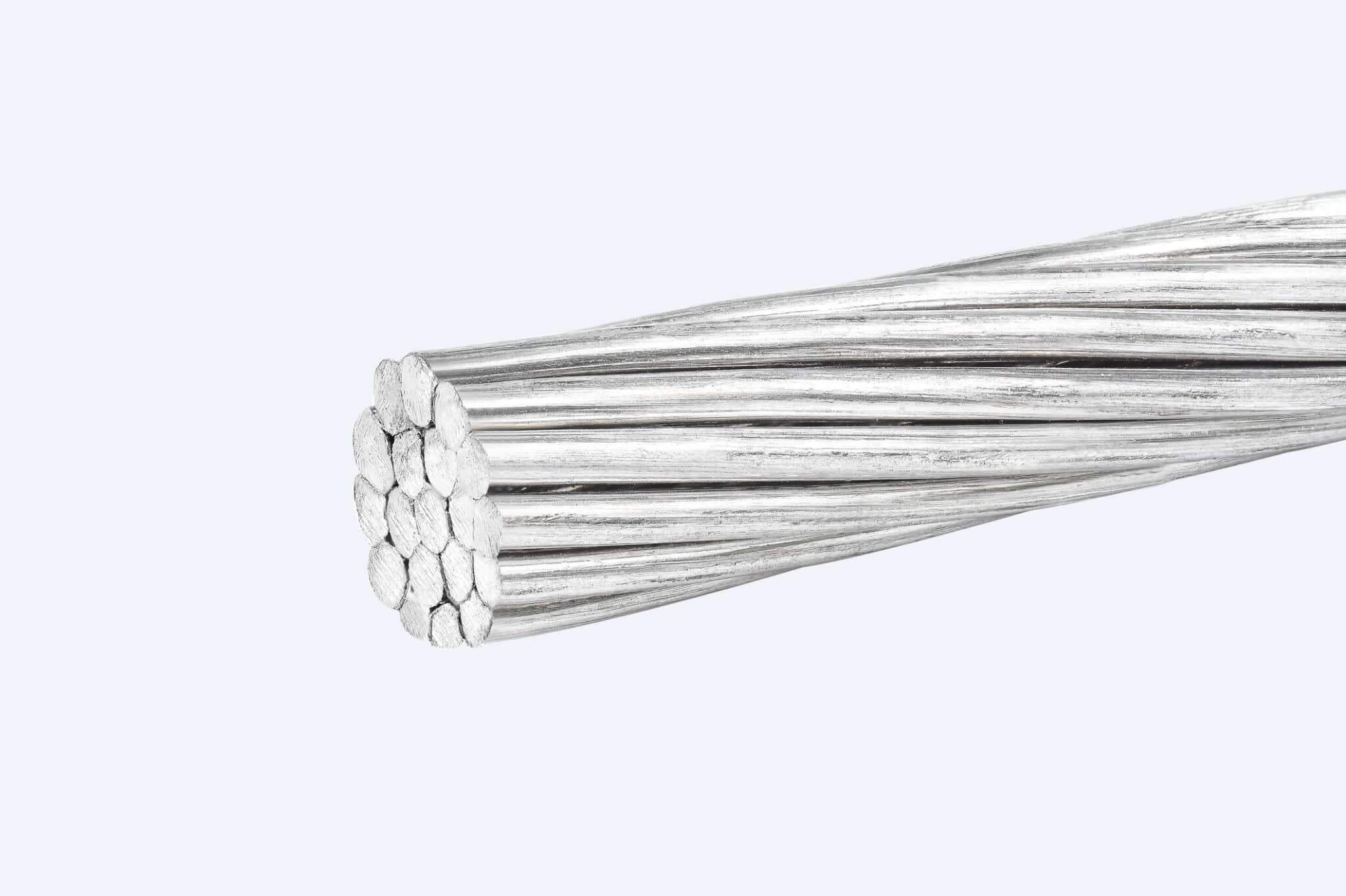

What is Aluminum Wiring?

In the 1960s and 1970s, aluminum wiring was commonly used in residential buildings as a cheaper alternative to copper wiring. Homeowners and builders preferred it because of its lower installation costs. However, over time, various issues emerged that revealed the drawbacks and dangers of using aluminum for electrical systems.

Unlike copper, aluminum is softer and tends to expand and contract more. This makes it more likely to loosen connections, leading to overheating. Additionally, this type of wiring is prone to oxidation, creating resistance at connections and increasing the risk of electrical fires. These problems were not fully understood when aluminum was first adopted, resulting in its widespread use in many homes.

Understanding the history and characteristics of this type of wiring helps highlight why it has become a safety concern. As we explore further, you’ll learn about the specific risks and what can be done to ensure your home’s electrical system is safe.

Why is Aluminum Wiring a Safety Hazard?

The primary concern lies in the differences between aluminum wiring and copper wiring. Aluminum tends to expand and contract more than copper, which can cause connections to loosen over time. Loose connections lead to overheating, significantly increasing the risk of electrical fires.

Oxidation is another critical issue. Aluminum oxidizes more easily than copper, forming a layer that creates resistance at connections.

This resistance generates heat, posing a further fire hazard. Additionally, aluminum has a higher electrical resistance, meaning it needs to be larger to carry the same current as copper. If not properly sized, aluminum wires can overheat.

Signs of Aluminum Wiring Problems

Recognizing the warning signs of wiring problems in your home early can help prevent serious issues. Here are some common indicators to watch for:

Flickering Lights: One of the most noticeable signs. This can occur when connections become loose, causing intermittent contact and sparking. If your lights are dimming or flickering frequently, it could indicate an underlying problem with your electrical system.

Warm Outlets and Switches: When connections overheat, they transfer heat to the surrounding components. If an outlet or switch feels warm or hot to the touch, it’s a clear sign that something is wrong and needs immediate attention.

Burn Marks and Melted Insulation: These are more serious symptoms indicating that the wiring is overheating. Burn marks around outlets or melted insulation are significant fire hazards. If you notice any burn marks or melted materials, it’s crucial to have a professional inspect your wiring immediately.

Buzzing or Crackling Sounds: Unusual sounds coming from your outlets, switches, or the electrical panel can indicate a problem. These noises are often caused by loose connections or electrical arcing, which can be dangerous if not addressed promptly.

Tripped Circuit Breakers: Frequent tripping of circuit breakers or blown fuses can signal an issue with your wiring. This could be due to overloaded circuits or problems with the connections, both of which require professional assessment.

Sparking Outlets: If you see sparks when plugging or unplugging appliances, this is a serious warning sign. Sparking can indicate loose connections or damaged wiring, both of which pose a fire risk.

Discolored or Scorched Outlets and Switches: Discoloration or scorch marks on your outlets and switches can result from overheating. This is a clear sign that the wiring behind the outlet or switch is getting too hot and needs immediate attention.

Unusual Odors: A burning smell near outlets, switches, or the electrical panel is a sign of overheating wiring. This could lead to a fire if not addressed promptly by a professional.

Being aware of these signs can help you catch problems early and address them before they escalate into more dangerous situations. Regular inspections and prompt action are key to maintaining a safe electrical system in your home.

Potential Risks Associated with Aluminum Wiring

Understanding the risks associated with this type of wiring is crucial for maintaining a safe home. Here are some of the primary concerns:

Increased Risk of Electrical Fires: This wiring is more prone to overheating due to its higher electrical resistance and tendency to loosen at connections. This overheating can lead to electrical fires, making it a significant safety hazard.

Insurance Implications: Many insurance companies are wary of homes with this type of wiring due to the increased risk of fire. Some may charge higher premiums or even refuse coverage unless the wiring is inspected and properly maintained. It’s important to check with your insurance provider to understand how it affects your policy.

Connection Failures: The expansion and contraction of aluminum can cause connections to deteriorate faster than copper. This deterioration can lead to loose connections, arcing, and sparks, which further increases the risk of fire and electrical shocks.

Incompatibility with Modern Fixtures: This wiring may not be compatible with many modern electrical fixtures and devices. Using incompatible fixtures can exacerbate the risks, leading to potential overheating and failures.

Higher Maintenance Costs: Homes with this type of wiring often require more frequent inspections and maintenance to ensure safety. Over time, these costs can add up, making it a less economical choice in the long run.

Potential Legal Issues: If you’re selling your home, this type of wiring might be a sticking point in negotiations. Potential buyers may request repairs or rewire before finalizing a purchase, or it may affect the marketability and value of your home.

Recognizing these risks highlights the importance of addressing any issues promptly. Ensuring your wiring is safe and up to current standards can protect your home and provide peace of mind.

Inspection and Identification of Aluminum Wiring

Identifying aluminum wiring in your home is essential for maintaining electrical safety. Here are the steps to determine if your home has this type of wiring:

Check the Electrical Panel and Look for Markings: Look inside the electrical panel for markings on the wires. This type of wiring is typically labeled with “AL,” “ALUM,” or “ALUMINUM.”

Inspect Visible Wires: Examine any visible wiring, such as in the attic, basement, or around outlets. Aluminum wires are generally silver-colored, unlike the distinct copper hue of copper wiring.

Check Outlet and Switch Connections: Carefully remove the outlet and switch covers to inspect the wiring. If the wires connected to the terminals are silver-colored, they are likely aluminum. Ensure the power is turned off before performing this inspection.

Use a Flashlight: When inspecting wires in dark areas such as basements or attics, use a flashlight to clearly see the color and markings on the wiring.

Consult Home Inspection Reports: Review any available home inspection reports if you recently purchased the home. Inspectors often note the type of wiring present, which can provide valuable information about your electrical system.

While a preliminary inspection can be done by homeowners, it’s crucial to have a professional electrician conduct a thorough examination. Professional inspections ensure all wiring is correctly identified and assessed for safety.

The importance of professional electrical inspections cannot be overstated. Licensed electricians have the expertise to spot potential hazards that might be missed during a casual inspection. They can also recommend appropriate actions to mitigate any risks associated with it.

Regular inspections by qualified professionals help maintain the safety and efficiency of your home’s electrical system, giving you peace of mind.

Solutions and Safe Practices for Aluminum Wiring Issues

Addressing aluminum wiring issues is crucial for ensuring the safety of your home. Here are some effective solutions and safe practices to follow:

Complete Rewiring with Copper: The most comprehensive solution is to replace all aluminum wiring with copper. Copper is more stable and poses fewer risks. Although this can be costly and time-consuming, it provides a long-term fix that significantly improves safety.

Pigtailing: This method involves connecting a short piece of copper wire to the ends of the aluminum wires using special connectors. This approach helps mitigate risks by improving connections and reducing the chances of overheating. It’s a less invasive and more affordable option compared to complete rewiring.

Use of CO/ALR Rated Connectors and Devices: CO/ALR (Copper Aluminum Revised) connectors and devices are specifically designed for use with this type of wiring. These products are tested and certified to handle the unique properties of aluminum, reducing the risk of overheating and fires. Replacing standard electrical devices with CO/ALR-rated ones is a practical way to enhance safety.

Application of Antioxidant Paste: Applying an antioxidant paste to connections can help prevent oxidation, which is a common problem with aluminum. This paste reduces resistance at connections, lowering the risk of overheating.

Regular Inspection Schedules: Schedule regular inspections by a licensed electrician to check for any signs of wear and tear. Regular inspections can identify issues before they become serious problems, ensuring your electrical system remains safe and functional.

Upgrading Electrical Panels and Outlets: Consider upgrading to CO/ALR-rated connectors and devices, which are designed to handle the unique properties of aluminum. This can prevent overheating and ensure safer connections throughout your home.

Avoid Overloading Circuits: Ensure that circuits are not overloaded. Overloading can cause overheating and increase the risk of fires. Spread out the use of high-wattage appliances to avoid putting too much strain on any single circuit.

Immediate Attention to Warning Signs: Address any signs of electrical problems immediately, such as flickering lights, warm outlets, or burn marks. These symptoms indicate potential issues that need prompt attention to prevent more serious hazards.

By implementing these solutions and following these safe practices, you can significantly reduce the risks associated with this wiring and enhance the safety of your home. Regular maintenance and prompt attention to issues are key to ensuring the safety and efficiency of your electrical system.

The Role of Professional Electricians in Mt. Pleasant

Hiring a professional electrician is essential when dealing with aluminum wiring, especially in a growing community like Mt. Pleasant. Here’s why:

Expertise and Experience: Licensed electricians in Mt. Pleasant have the knowledge and experience to handle specific challenges and potential hazards safely. They ensure all work complies with safety standards and local building codes.

Proper Techniques and Tools: Professional electricians use the correct techniques and tools for working with this type of wiring. For instance, they use CO/ALR-rated connectors and devices, reducing the risk of poor connections and overheating.

Identification of Potential Issues: Electricians can spot problems that might not be obvious to homeowners, such as signs of oxidation, loose connections, and overheating. Early detection of these issues can prevent more serious problems, ensuring the safety of homes in Mt. Pleasant.

Compliance with Code Requirements: Electrical work must comply with local regulations. Professional electricians in Mt.Pleasant ensure all repairs and modifications meet these requirements, preventing potential legal issues and ensuring high standards.

Common Mistakes to Avoid: Handling this type of wiring without proper knowledge can lead to dangerous mistakes, such as using incompatible connectors or failing to apply antioxidant paste. Professional electricians avoid these errors, ensuring the work is done correctly and safely.

Hiring a licensed and experienced electrician in Mt.Pleasant is crucial for addressing these issues effectively. Their expertise ensures the safety and reliability of your home’s electrical system.

Ensure Your Home’s Safety: Contact Mister Sparky of Charleston Today!

If you live in Mt. Pleasant and are concerned about the safety of your home’s wiring, Mister Sparky of Charleston is here to help.

Our team of licensed and experienced electricians in Mt. Pleasant specializes in identifying and addressing issues with aluminum wiring.

We offer comprehensive inspections, safe upgrades, and expert maintenance services to ensure your home’s electrical system is safe and reliable.

At Mister Sparky of Charleston, we understand the unique challenges that aluminum wiring presents. Our skilled electricians are trained to handle these challenges with precision and care.

Whether it’s performing a thorough inspection to identify potential hazards, upgrading your electrical system with CO/ALR-rated connectors, or implementing pigtailing techniques, we have the expertise to enhance the safety of your home.

Don’t wait until a small issue becomes a major hazard. Contact Mister Sparky of Charleston today to schedule an inspection or consultation. We are committed to providing the highest quality service to keep your home safe and efficient.

Call us now to book your appointment or visit our website to learn more about our services. Your safety and satisfaction are our top priorities, and we strive to exceed your expectations with every service call.

FAQs about Aluminum Wiring

Are homes with aluminum wiring safe?

Homes with aluminum wiring can be safe if properly maintained. Regular inspections by a licensed electrician are crucial to identify and address potential issues that could lead to overheating or fires. Proper maintenance, such as using CO/ALR-rated connectors and applying antioxidant paste, can help mitigate the risks associated with this type of wiring. However, it’s important to remain vigilant and address any problems promptly to ensure ongoing safety.

What should I do if my house has aluminum wiring?

If your house has aluminum wiring, the first step is to schedule an inspection with a professional electrician. They can assess the condition of the wiring and recommend appropriate measures to enhance safety. These measures may include pigtailing, which involves connecting the copper wire to the ends of aluminum wires or upgrading to CO/ALR-rated connectors and devices specifically designed for aluminum. Following the electrician’s recommendations can significantly reduce the risks associated with this wiring.

How often should aluminum wiring be inspected?

Aluminum wiring should be inspected at least once every few years. Regular inspections help catch any potential problems early, ensuring your home remains safe. During these inspections, electricians check for signs of wear and tear, loose connections, oxidation, and other issues that could pose a risk. By identifying and addressing problems early, you can prevent more serious hazards and maintain the safety and efficiency of your electrical system.

Can I sell my house if it has aluminum wiring?

Yes, you can sell your house if it has aluminum wiring, but it may affect the sale. Potential buyers might request repairs or upgrades before finalizing the purchase, as this wiring can be a concern for safety and insurance purposes. Ensuring your wiring is in good condition and up to code can help with the sale process. Providing documentation of recent inspections and any safety upgrades can also reassure buyers and potentially smooth the transaction.

What are the signs that my aluminum wiring needs attention?

Signs that your wiring needs attention include flickering lights, warm outlets, and switches, and burn marks or melted insulation. Flickering lights can indicate loose connections or intermittent contact. Warm outlets and switches suggest overheating, which is a serious safety concern. Burn marks or melted insulation are clear indicators of overheating and potential fire hazards. If you notice any of these issues, contact a licensed electrician immediately to inspect and repair your wiring.